Edge processing

- along one of the lenghts of the slab, when the piece is designed to be a window sill,

- along the two lenghts of the slab, when the piece is designed to be part of a fence or a cap.

- along one of the lenghts and right/left sides for steps according to the place of mounting.

| Upon request | |

| Price / Unit | Price per linear meter |

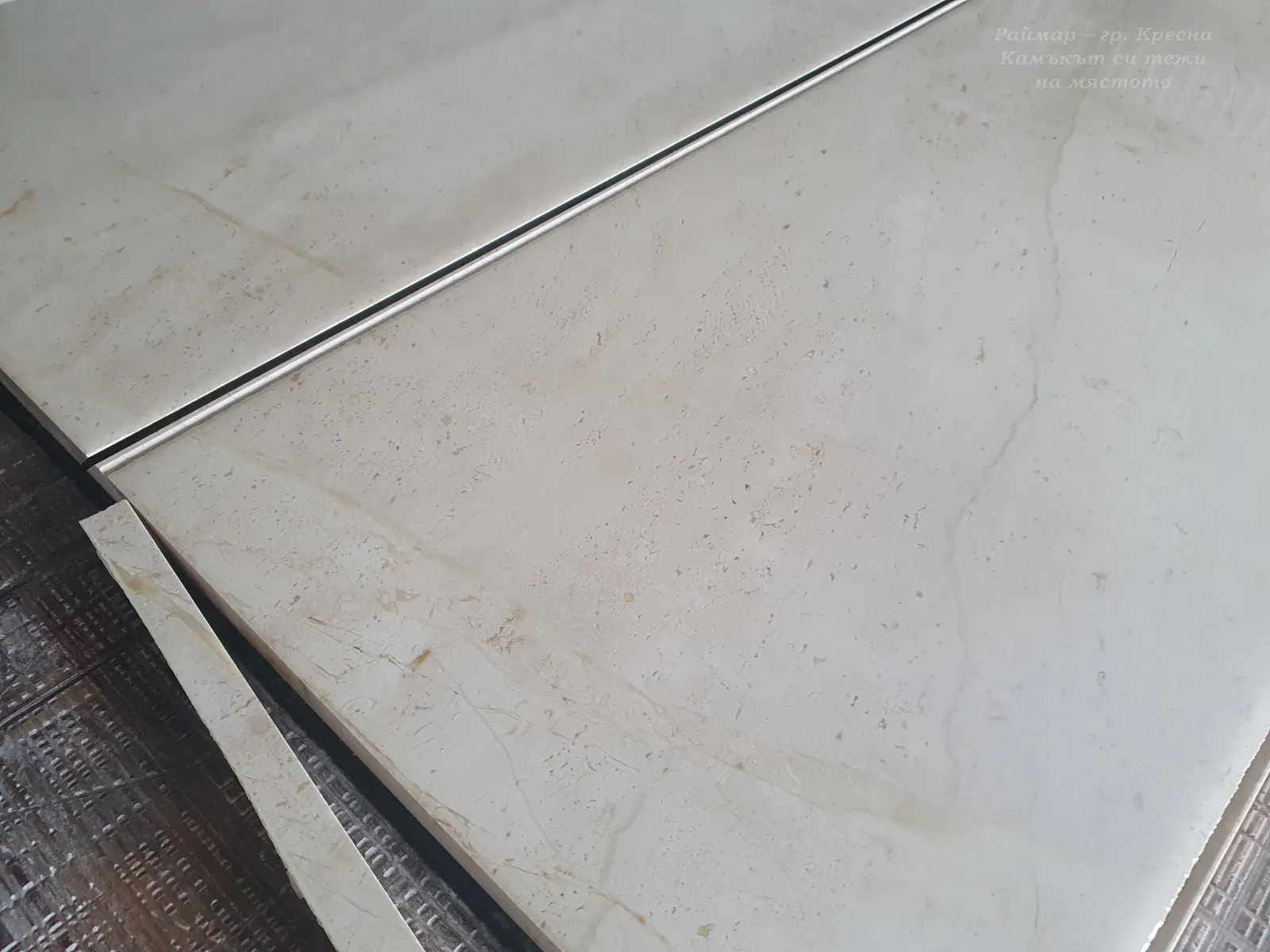

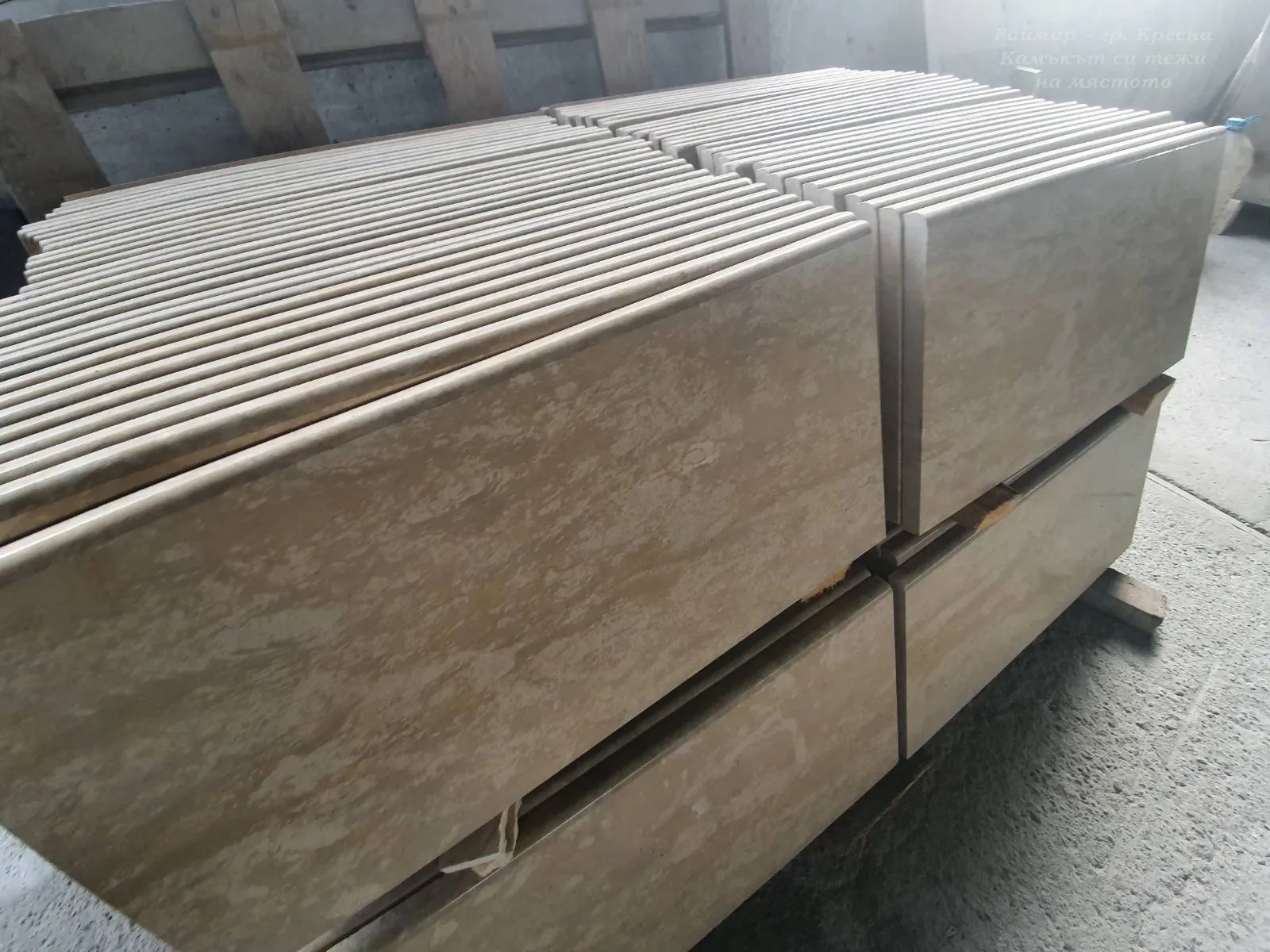

| Natural stone specifics | Possible deviations and variations in the colors and textures of the stone tiles are expected (resulting from the natural origin and formation of the stone). |

| The cut to size stone tiles have nominal dimensions with a tolerance of up to ± 3mm (not calibrated). | |

| Always plan for a 10% advance on the net square footage | |

| Our products are handmade craftsmanship, made by artisans (stone masons). | |

| Recommended adhesives | Cement adhesive class C2TES1: C - cementitious, 2 - improved strength properties, T - fixing, anti-slip, E - extended open time, S1 - elastic, for linear expansions (+ addition of TRAS against salt appearance/efflorescence) |

| For white and light materials: white cement adhesive SuperFix Flex C2TE BAUMASTER | |

| For exterior and interior: gray cement adhesive MegaFlex C2TES1 BAUMASTER | |

| Protection, mandatory impregnation, and maintenance (LTP or AKEMI) | For protection against water absorption: Universal stone impregnator (LTP or AKEMI) |

| For protection against water and grease absorption: Stone impregnator Mattstone H2O | |

| Always clean natural stone with pH-neutral products only (LTP or AKEMI). | |

| For color enhancement and protection: Wet effect impregnator (LTP or AKEMI). |

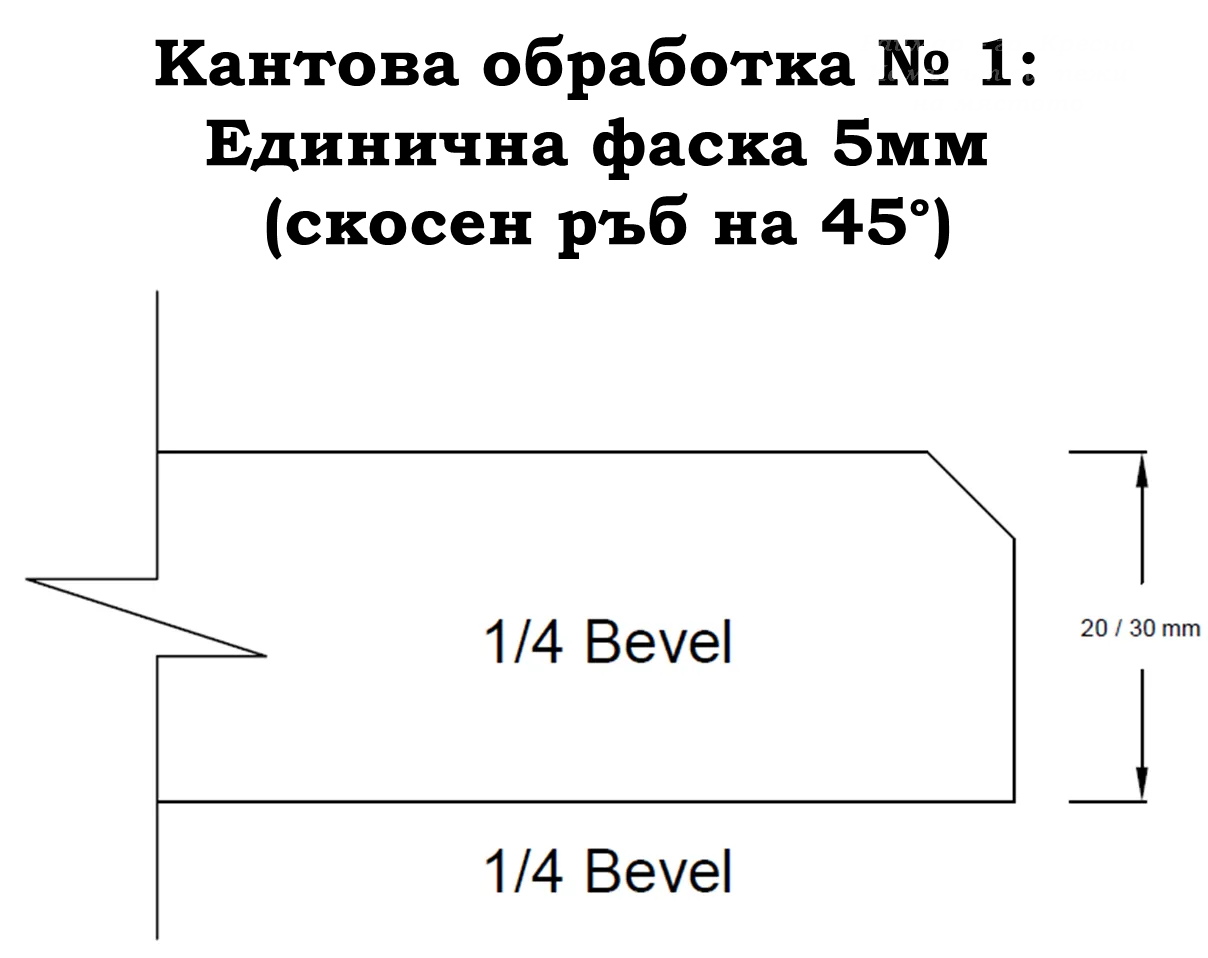

The price of 12 BGN/meter is for Edge Treatment No. 1: single bevel on the top edge for granite. 9 BGN/meter applies to all other materials.

Contact us for a quote on other types of edge treatments for stone slabs.

Send us your dimensions with your preferred material, and we will propose a detailed cost estimate based on the order quantity, as well as transportation to your specified address.

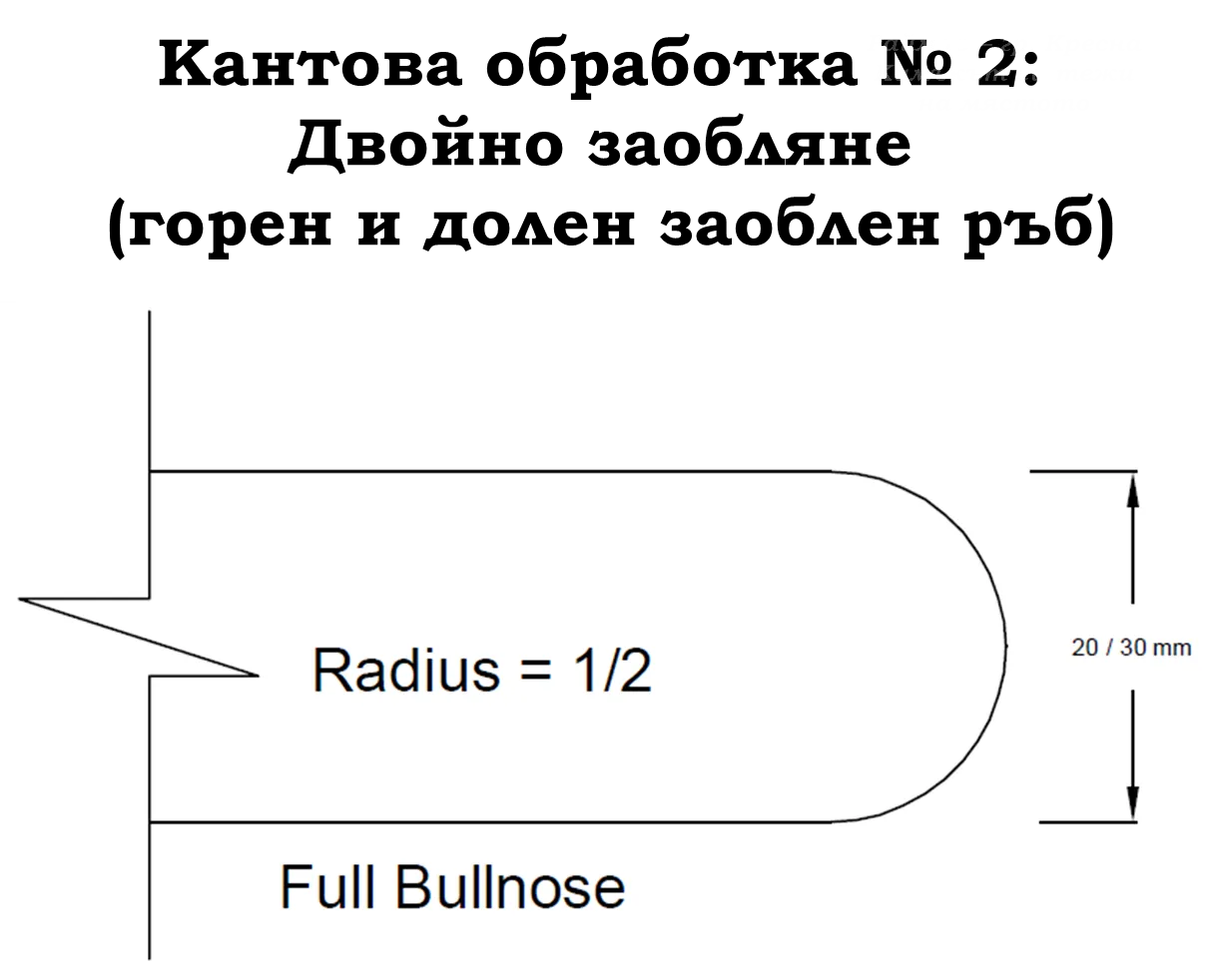

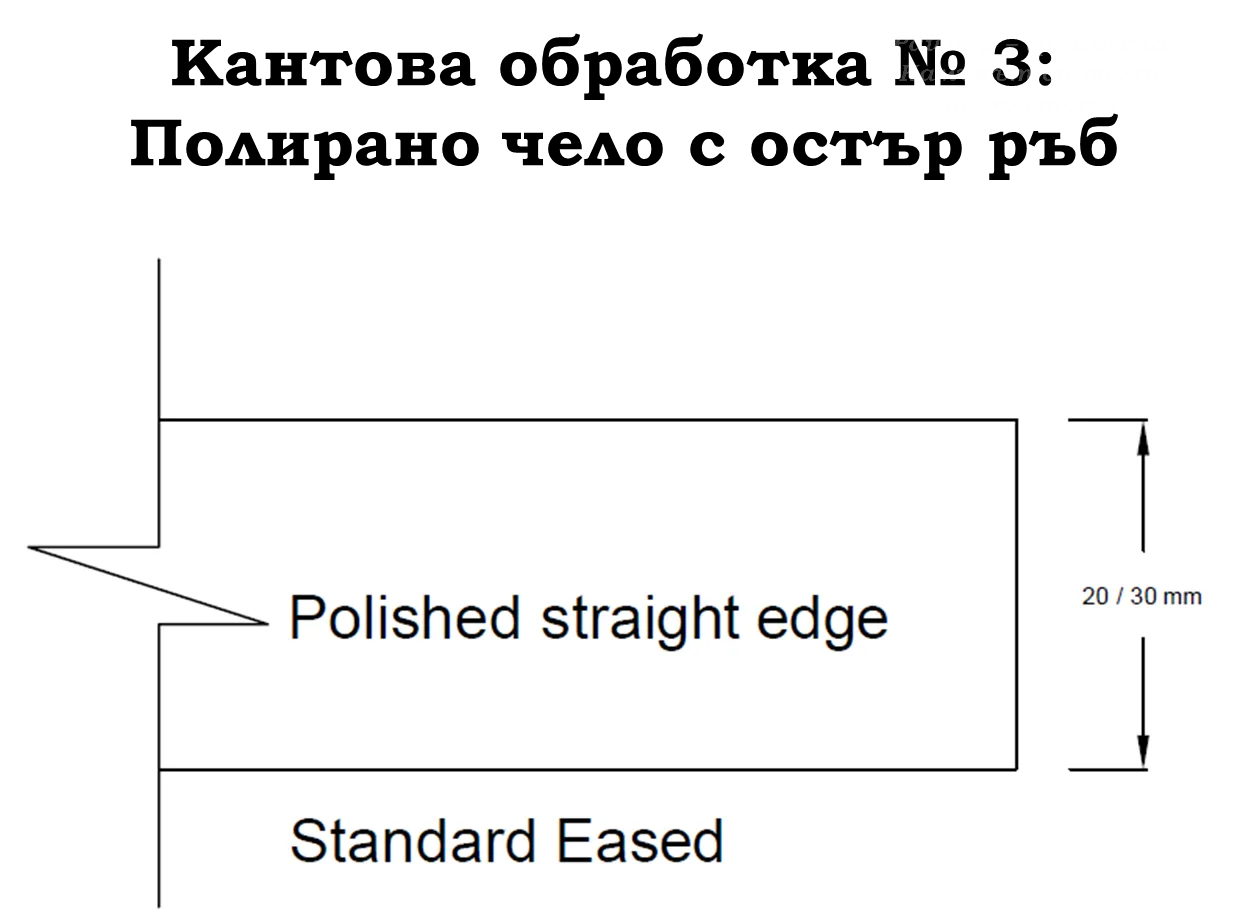

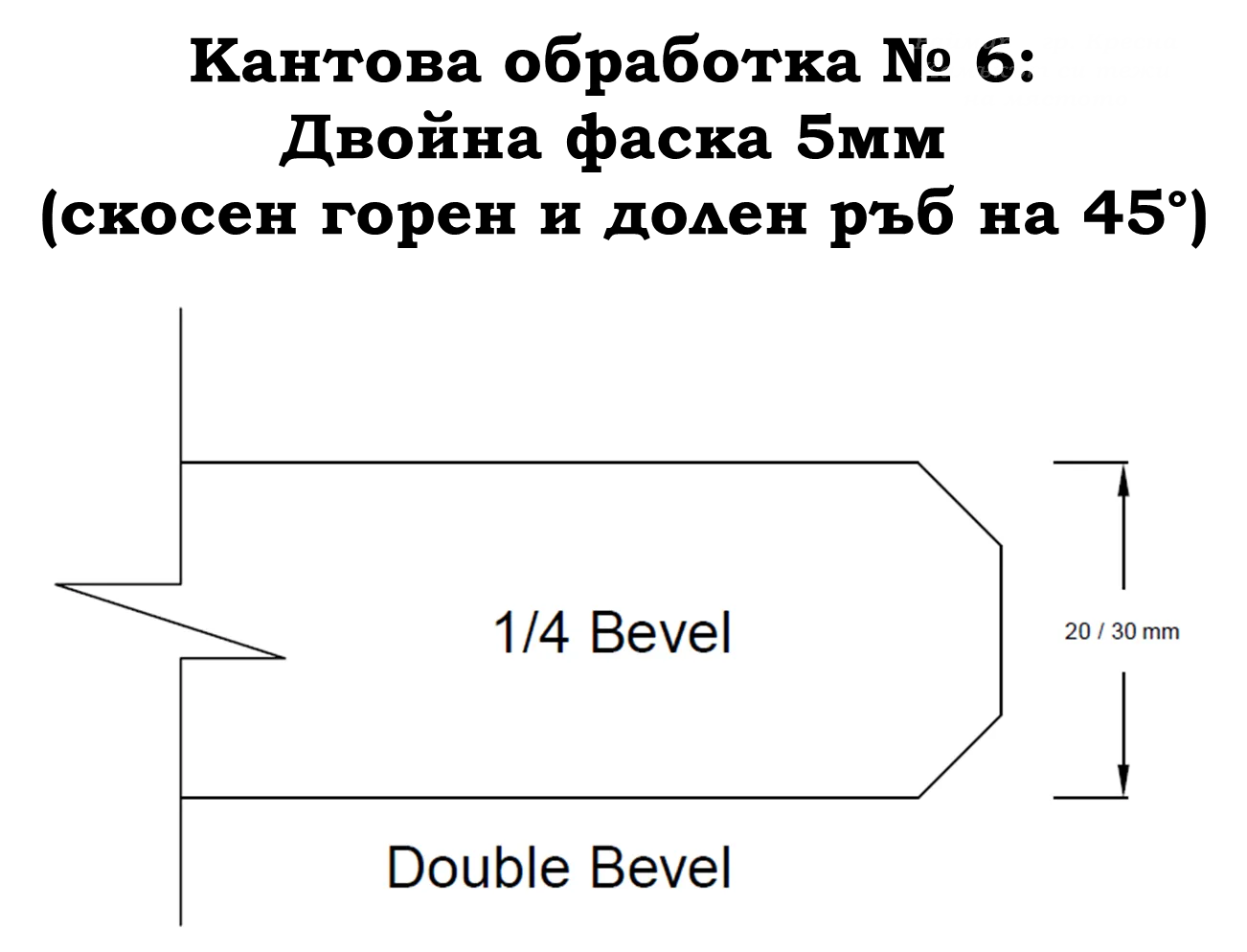

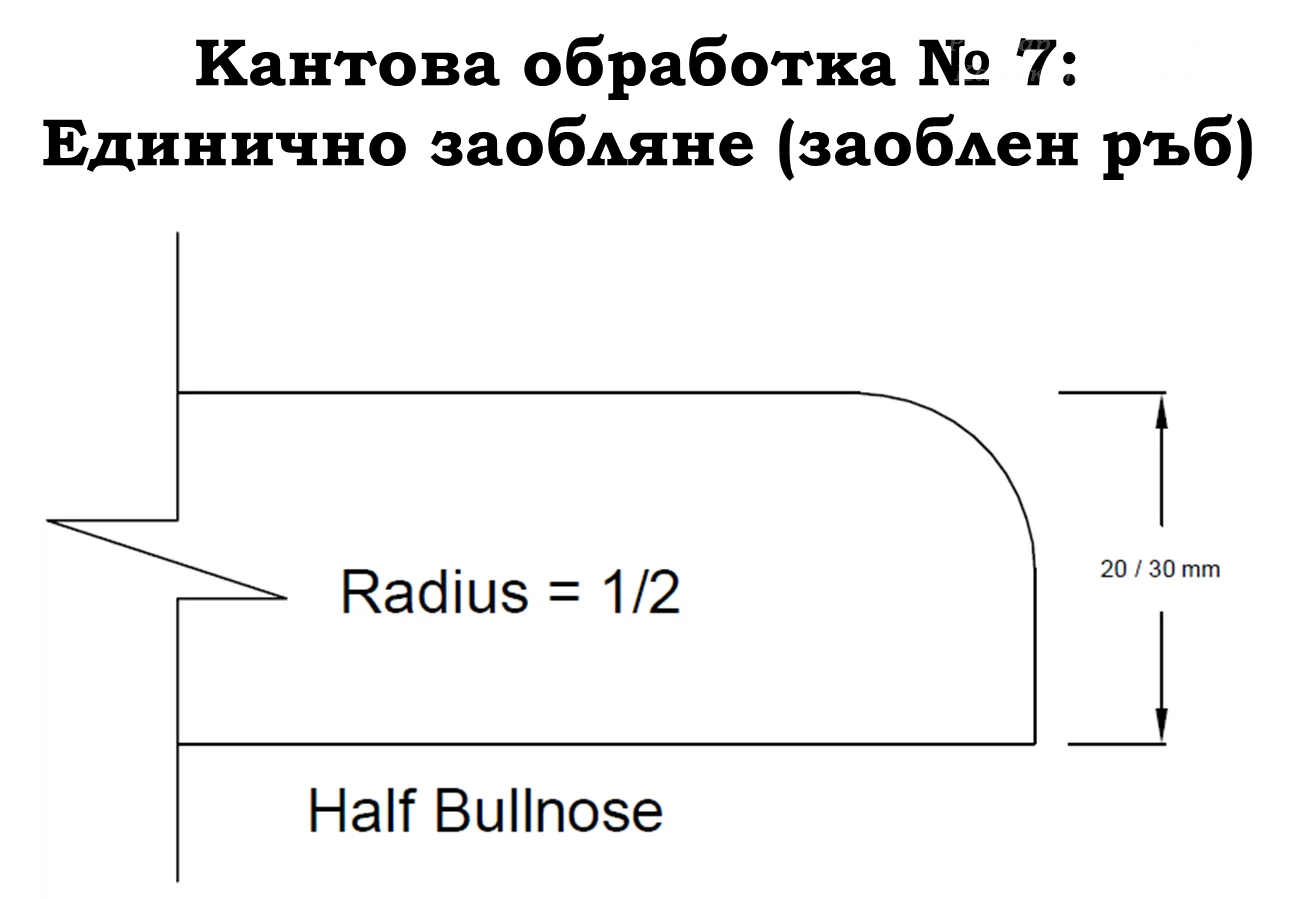

The possible ways to treat the edges along the lengths or widths of slabs for window sills, fence caps, terrace caps, thresholds, countertops, and stairs made from marble, travertine, and granite are:

- 45-degree bevel (angled edge): This is the most popular and preferred way to finish the edge.

- Double rounding (rounded top and bottom edge)

- Polished face with sharp edge

- Double backing with full double rounding

- Drip edge: The drip edge is 1 cm from the edge of the slab and has a width of 5 mm.

- Double 45-degree bevel (both top and bottom angled edges)

- Single rounding (rounded edge)

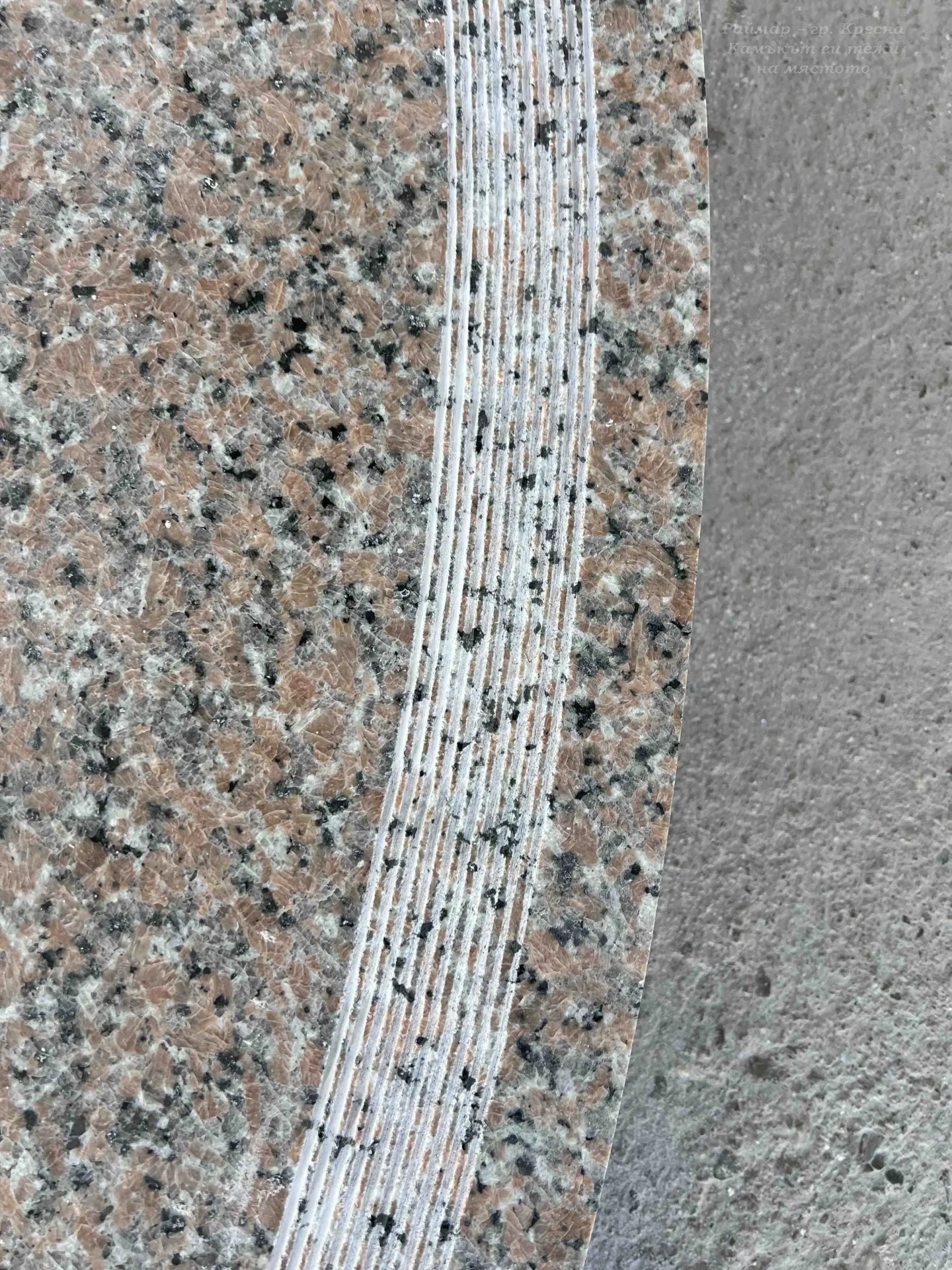

- Anti-slip grooves: These are three parallel indented lines along the face of the stair to provide extra safety and grip.

No. 1: Single bevel is the most preferred option for profiling stone edges because it has a modern appearance and is machine-processed.

No. 5: Drip edge: The drip edge, or drip channel, is a line cut from the bottom of the slab to protect wall plaster or cladding. It is used only in exterior applications where slabs might get wet due to washing or rain. We recommend drip edges for exterior stairs, terrace caps, and external window sills.

No. 5: The groove for the drip edge can also serve as a slot for under-lighting for interior stairs: The under-lighting looks the same as the drip edge, but the line cut from the front lower part of the stone slabs is slightly thicker. In the groove (slot) for lighting, you can install flexible, self-adhesive LED strips/under-lighting. This feature provides a highly aesthetic look for indoor marble, granite, or travertine staircases and is also an important safety factor.

No. 8: Anti-slip lines for stairs: These are three indented parallel lines along the length of the stair to ensure greater safety. This gives the stair a rough area that is less slippery. Anti-slip lines are preferred for indoor or outdoor staircases made of polished materials (marble, granite, limestone, or travertine). They look equally good and work well for outdoor staircases made from antiqued travertine or flamed granite.

Edge treatment of the slabs is an important element of design, affecting the efficiency, safety, and style of the interior or exterior. The secret to our high-quality treatment lies in the attention to detail and a love for perfection. We are driven by our admiration for the majestic beauty of natural stone.

Български

Български