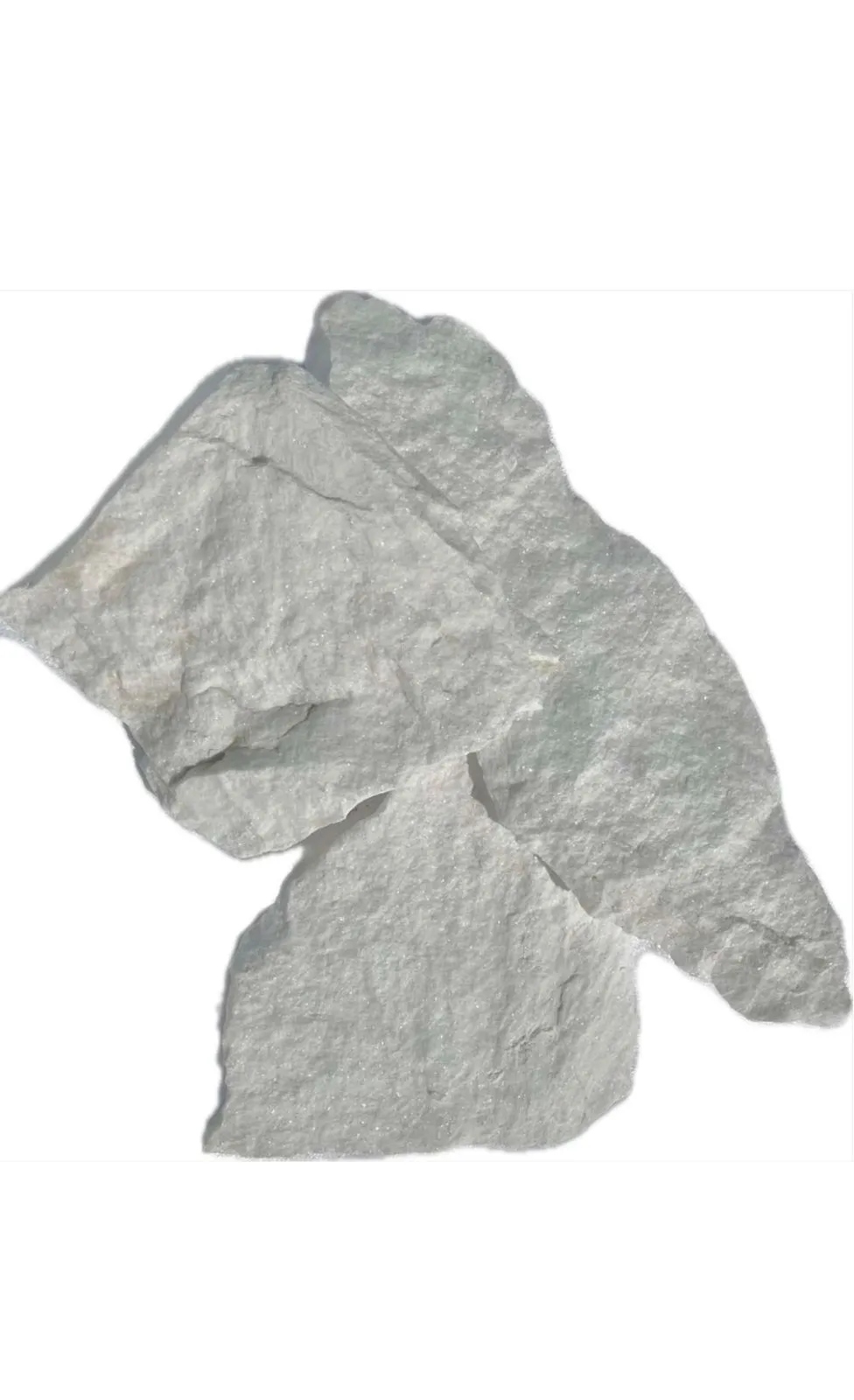

Thassos marble veneers and corners with cut back

| Available | |

| Material | Marble |

| Natural stone | Thassos marble |

| Finish | Natural |

| Price / Unit | Price per 1 sq.m |

| Price per linear meter | |

| Pallet | |

| Maximum pallet weight | 10-15 sq.m = 990 kg |

| Thickness of the tiles | 2-5 cm |

| Natural stone specifics | Possible deviations and variations in the colors and textures of the stone tiles are expected (resulting from the natural origin and formation of the stone). |

| Always plan for a 10% advance on the net square footage | |

| Our products are handmade craftsmanship, made by artisans (stone masons). | |

| Pre-sorting by color or caliber, as well as preferences for nuances, patterns, or color variations in the stone, is not possible in advance. | |

| Recommended adhesives | Cement adhesive class C2TES1: C - cementitious, 2 - improved strength properties, T - fixing, anti-slip, E - extended open time, S1 - elastic, for linear expansions (+ addition of TRAS against salt appearance/efflorescence) |

| Protection, mandatory impregnation, and maintenance (LTP or AKEMI) | For protection against water absorption: Universal stone impregnator (LTP or AKEMI) |

| For protection against water and grease absorption: Stone impregnator Mattstone H2O | |

| Always clean natural stone with pH-neutral products only (LTP or AKEMI). | |

| For color enhancement and protection: Wet effect impregnator (LTP or AKEMI). |

Masonry made of white marble is a perfect combination of natural elegance and exquisite craftsmanship. White marble, with its purity and smooth texture, gives buildings and decorative elements not only a refined look but also a sense of luxury and timelessness. Its characteristic light shades reflect light in a unique way, creating a play of shadows and brilliance that adds depth and life to any surface. The beauty of white marble masonry lies in its durability, its ability to retain its magnificent appearance through the ages, and the skill of the craftsmen who bring this noble stone to life through their art.

The installation process for masonry (caps and corners with cut back) for cladding typically includes the following steps:

Surface Preparation: Ensure the surface where the stone slabs will be installed is clean, stable, and free of dust, dirt, or grease. If necessary, remove cracks or imperfections and apply a weather-resistant underlay.

Layout and Design Planning: Design the layout and arrangement of the stone tiles for cladding, considering the desired combination of colors, aesthetics, and architectural elements. Temporarily place the stones without adhesive (dry lay) to determine the best arrangement and make necessary adjustments.

Applying Adhesive: Apply a suitable adhesive to the back of each stone using a notched trowel. Ensure you apply enough adhesive to secure proper bonding with the base.

Setting the Stones: Firmly press the stone slab with the smooth, cut back onto the prepared surface, starting from the bottom upwards. Use a slight twisting motion to ensure good contact between the stone and the adhesive. Maintain even spacing between the stones to achieve a uniform appearance.

Filling the Joints: Once the stones are set, fill the spaces between them with grout, depending on the desired effect.

Cleaning and Finishing: After the grout has partially set (follow the manufacturer’s instructions), clean the cladding surface with a brush and water. Carefully remove any excess adhesive or grout from the stone surface. Allow it to dry completely.

Impregnation: Depending on the type of stone and personal preferences, apply an impregnating sealer to the stone, which will enhance its appearance, protect it from stains, and increase its durability. Follow the manufacturer’s instructions for proper application and drying time.

It is important to note that the installation process may vary depending on the specific product, manufacturer guidelines, and the condition of the substrate.

Additionally, adhering to safety requirements during installation is essential. Follow all necessary precautions, wear protective clothing, and consult local building codes and regulations for guidance on installing stone masonry.

Български

Български