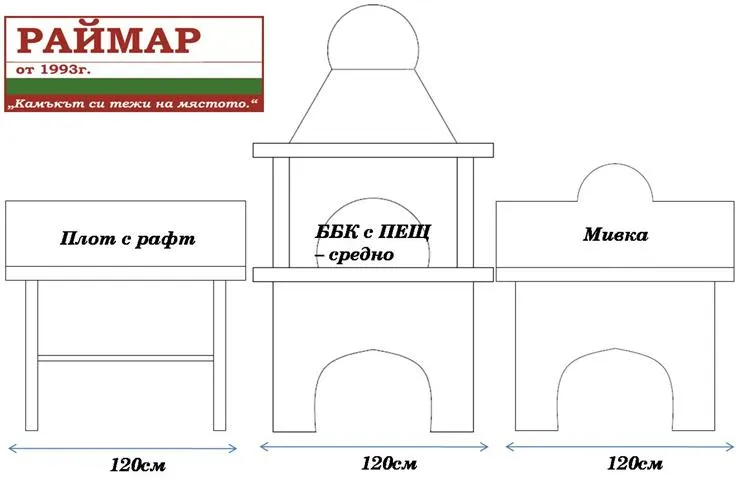

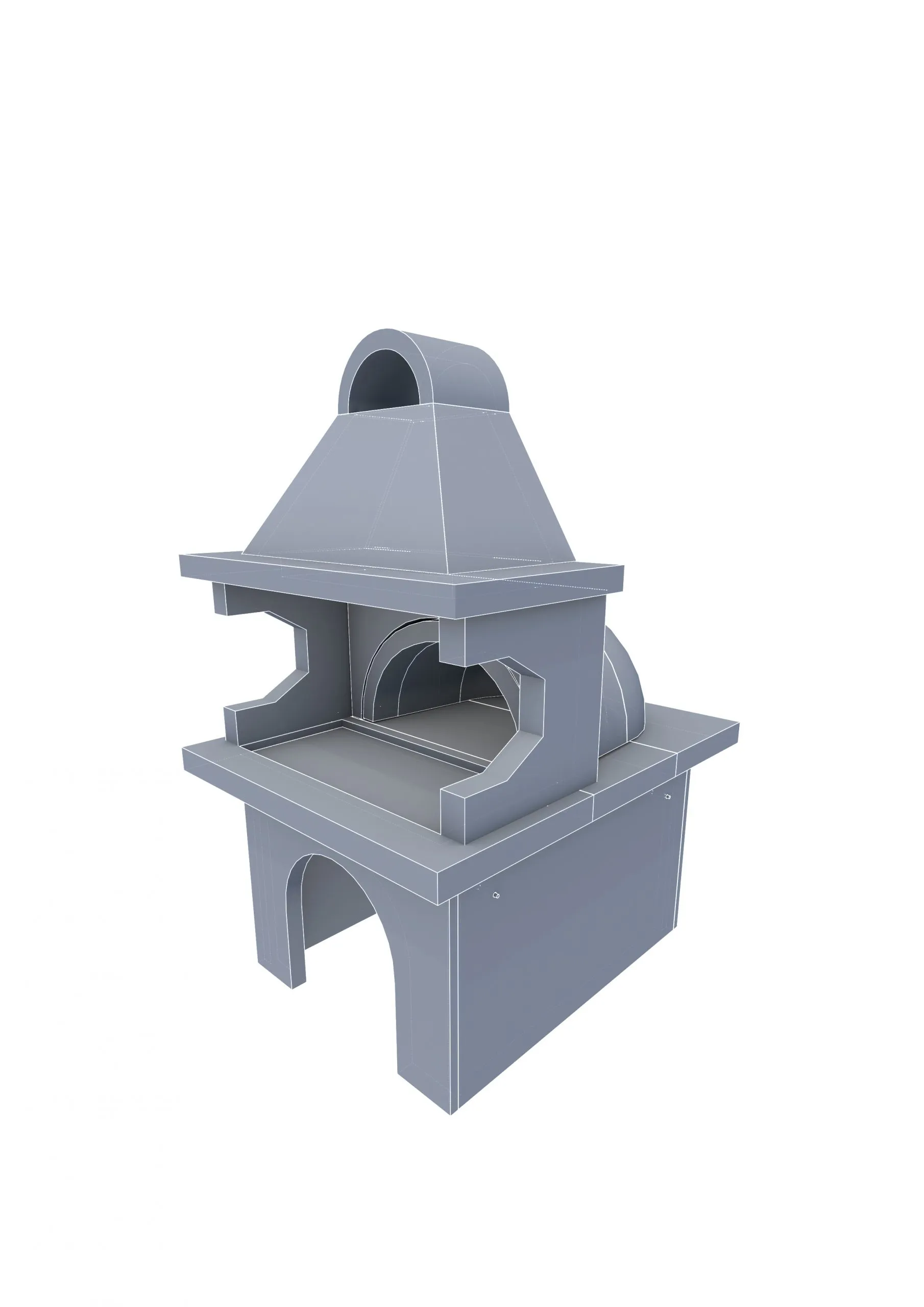

Medium barbecue with small oven | Standard series

| Production lead time | |

| Type cladding | Standard |

| Material | Gneiss |

| Price / Unit | Price for 1 piece |

| Pallet | |

| Natural stone specifics | Possible deviations and variations in the colors and textures of the stone tiles are expected (resulting from the natural origin and formation of the stone). |

| Our products are handmade craftsmanship, made by artisans (stone masons). | |

| Recommended adhesives | Gray polymer adhesive FLEXI (for silicone gun) |

| Black heat-resistant adhesive KALOFER (for silicone gun) | |

| Protection, mandatory impregnation, and maintenance (LTP or AKEMI) | For protection against water absorption: Universal stone impregnator (LTP or AKEMI) |

| For protection against water and grease absorption: Stone impregnator Mattstone H2O | |

| For color enhancement and protection: Wet effect impregnator (LTP or AKEMI). |

The combination of a furnace-oven with a barbecue is for every serious host who wants to pamper family and friends with freshly baked bread, kebabs, pizzas, or slowly roasted meat.

The oven is an excellent addition to the garden barbecue because it provides thousands of possibilities in a compact space and at a reasonable price.

While delicate meat is turning on the grill, appetizing pastries are baking in the oven, so that dining is richer and more delightful.

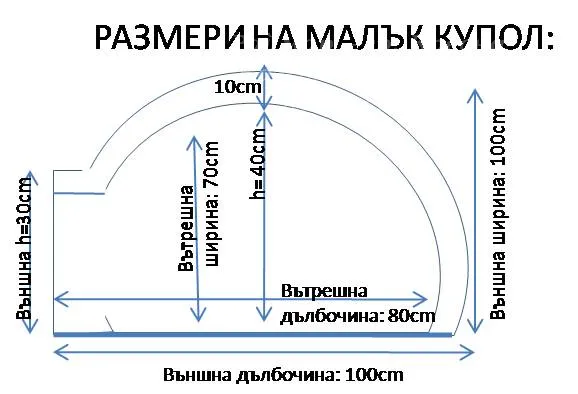

The largest lamb tray /standard size 60x40 cm/ can easily rotate in the oven. The wood-fired oven is an invaluable solution for handcrafted pizzas - a favorite at any garden party.

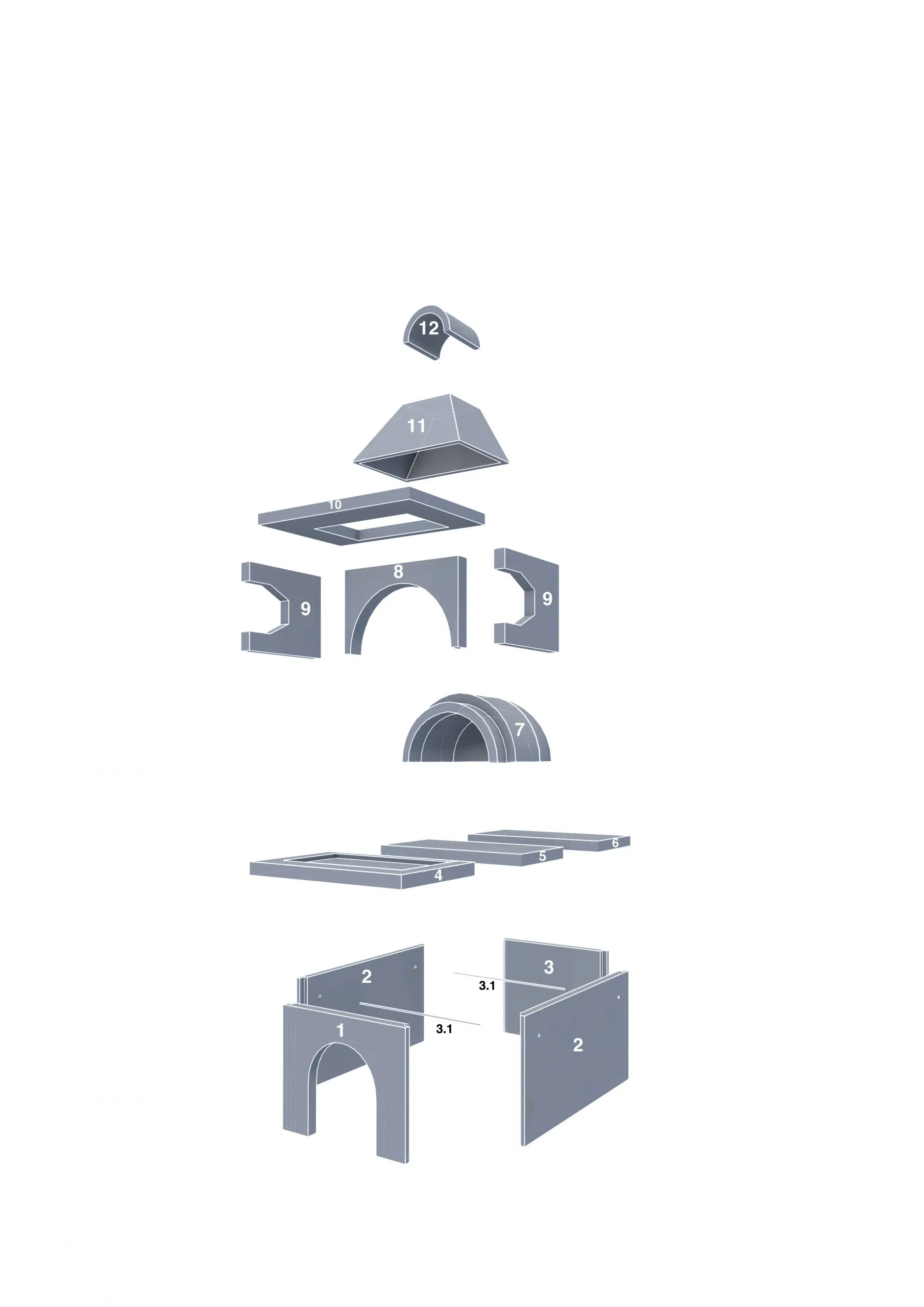

It's important to know that the combination of Medium Barbecue with Small Oven Standard is:

- with a masonry dome made of refractory chamotte bricks using an old Bulgarian technology;

- with a fire chamber of the barbecue made of ceramic refractory bricks, bonded with heat-resistant adhesive;

- for outdoor use, both outdoors and indoors;

- with reinforced concrete panels, clad with natural stone /handcrafted/;

- with an included metal lid for closing and sealing the oven after heating;

- arranged on 2 pallets for easy and possible pallet transport via courier;

- with the possibility to extend the chimney by adding AIR DUCTS;

- with the possibility to use various BARBECUE ACCESSORIES;

- with detailed General Assembly Instructions + Instructions for insulation and use of the ovens.

Practical use and modular assembly

How to use the barbecue: The fire pit is loaded with dry twigs and wooden coals. When igniting, abrupt temperature changes in the fire chamber should be avoided by using burners and petroleum products. After the fire is lit, the prepared products are arranged on the formed embers. During grilling, it is not recommended to extinguish the fire (abundantly) with water, only with spraying.

How to use the oven: Dry wood and twigs are placed in the middle of the dome of the oven. When igniting, abrupt temperature changes in the fire chamber should be avoided by using burners and petroleum products. After the initial ignition, it is normal for the bricks in the cube to turn red. The fire is maintained until the bricks turn white. The process of heating the oven takes about 2-3 hours. After they turn white, the oven is ready for baking, and the prepared tray is placed inside. Finally, the opening of the dome is closed with the iron lid and sealed with clay or a mixture of ash, flour, and water (paste).

Approximate assembly time by 3-4 beginners: 4-5 hours.

Amount of adhesive required for assembly: 25 kg Cement adhesive class C2 + Heat-resistant adhesive: 20 kg

The roof, air ducts, and adhesives are not included in the price. They are ordered separately.

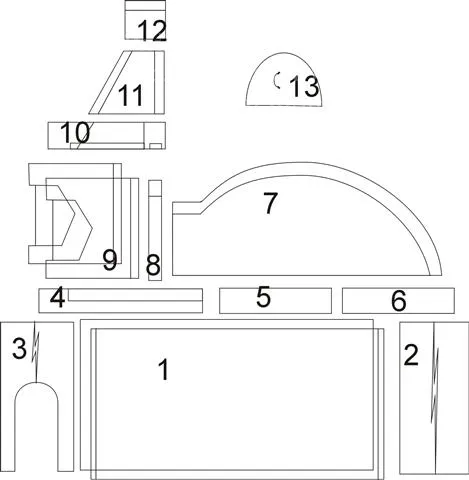

Assembly Instructions: An important condition for properly and easily mounting your furnace-barbecue is the platform. It must be stable, well-aligned, and leveled. The individual elements are assembled according to the numbering in the assembly instructions and glued with cement adhesive class C2. It is recommended that the elements in and around the dome be glued with heat-resistant adhesive. The individual parts should be generously moistened with water before applying the adhesive to ensure good adhesion. Level at each stage horizontally and vertically. The barbecue countertop is extended forward 15 cm from the base. The cube is placed at the beginning of the middle panel (the bottom of the fire pit). Finally, grout and clean well. After the adhesive has dried (from 12 to 24 hours depending on the season), your furnace-barbecue is ready to use.

The heaviest part is the dome, which weighs about 200 kg and requires a minimum of 4 people to move it.

Our useful tips

Recommendation for MANDATORY insulation of the oven: The better insulated the oven is, the greater the efficiency of baking, as the accumulated heat is preserved for a longer time. We recommend placing a cement roof on top of the cube of the oven and filling the empty space with quartz sand or marble flour (220 kg = 10 bags of 22 kg each). You can purchase such a roof from us.

Another option is to insulate the cube of the oven with aluminum foil insulation (3.5-4 sq.m), wire mesh, and finally to coat it with chamotte - refractory mixture, a mix of heat-resistant and cement adhesive.

Български

Български