Splitface oven

| Production lead time | |

| Type cladding | Splitface cladding |

| Sizes Garden Barbecues | 120/145/170сm |

| Material | Granite |

| Marble | |

| Limestone | |

| Finish | Splitface |

| Price / Unit | Price for 1 piece |

| Pallet | |

| Weight | 990 kg |

| Delivery via courier to address in Bulgaria | Transport for 1 industrial pallet max. 1 tonne 110 lv + 2% cash-on-delivery tax |

| Natural stone specifics | Possible deviations and variations in the colors and textures of the stone tiles are expected (resulting from the natural origin and formation of the stone). |

| Our products are handmade craftsmanship, made by artisans (stone masons). | |

| Recommended adhesives | Gray polymer adhesive FLEXI (for silicone gun) |

| Black heat-resistant adhesive KALOFER (for silicone gun) | |

| Protection, mandatory impregnation, and maintenance (LTP or AKEMI) | For protection against water absorption: Universal stone impregnator (LTP or AKEMI) |

| For protection against water and grease absorption: Stone impregnator Mattstone H2O | |

| For color enhancement and protection: Wet effect impregnator (LTP or AKEMI). |

These ovens are a temptation for those passionate about outdoor cooking, wood-fired flavors, and respect for natural materials and beauty.

The lining of light, genuine natural stone complements the presence of this unique garden oven, attracting and keeping family and friends in an atmosphere of warm conversation and the aroma of flatbreads, homemade pizza, and tender meats.

It's important to know that the ovens with splitface cladding are:

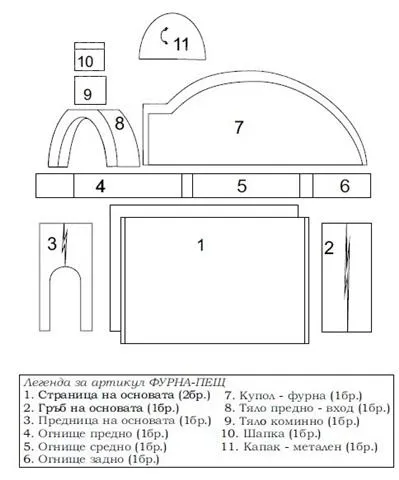

- with a brick dome built from fire-resistant refractory bricks following an old Bulgarian technology;

- with reinforced concrete panels lined with natural cut stone /handcrafted/;

- for outdoor use and open spaces;

- with an included metal cap for sealing the oven after heating;

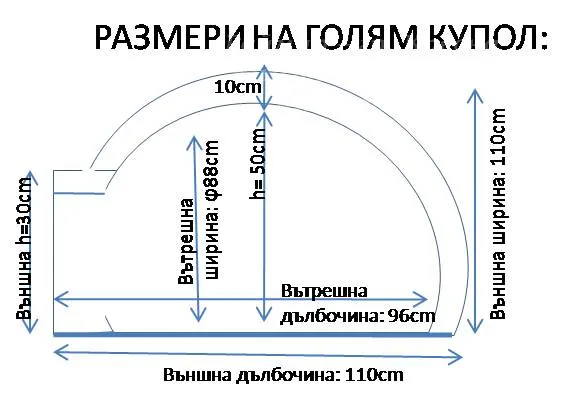

- with a dome opening width of 60 cm;

- with elements arranged on one pallet (industrial pallet size 1m x 1.20m for easy transport);

- with the option to extend the chimney with additional air ducts measuring 30x30cm and 15cm high;

- with the option to use various ACCESSORIES;

- with detailed installation instructions.

Practical Usage and Modular Assembly

Raymar – General Installation Instructions

Raymar – Insulation and Usage Instructions for the Ovens

Usage for Roasting Meat:

Dry wood and sticks are placed in the middle of the oven dome. When lighting, avoid sudden temperature changes in the combustion chamber by using burners or petroleum products. After initial ignition, it's normal for the bricks in the dome to turn black. The fire is maintained until the bricks whiten, typically taking around 2-3 hours. Once the bricks turn white, the oven is ready for roasting, and the prepared dish is placed inside. The dome opening is then closed with the metal cap and sealed with clay or a mixture of ash, flour, and water.

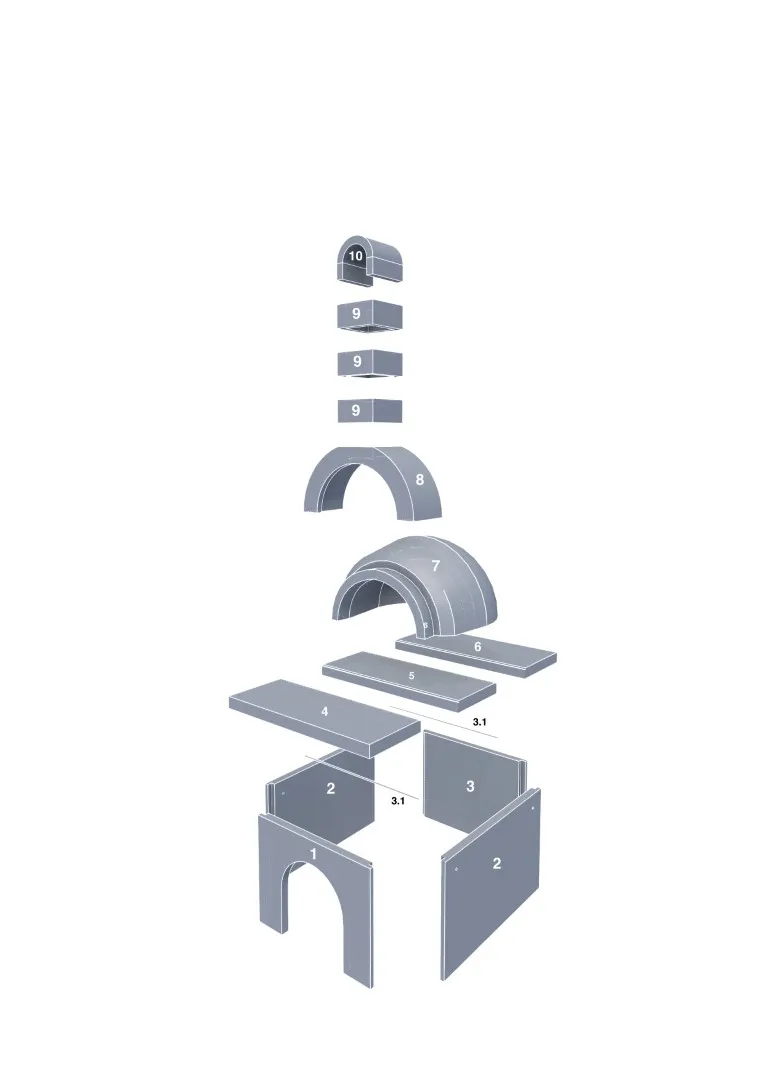

Approximate Assembly Time for 3-4 Beginners: 3-4 hours

Required Quantity of Adhesives for Assembly: 25 kg of cement adhesive (Class C2) + 20 kg of heat-resistant adhesive

Installation Instructions: A crucial condition for proper and easy oven installation is a stable, well-leveled, and even platform. The oven elements are assembled according to the numbering in the instructions and glued with cement adhesive (Class C2). It's recommended to use heat-resistant adhesive for the elements in and around the dome. Each part should be thoroughly dampened with water before applying the adhesive to ensure good adhesion. Finally, grout and clean. Once the adhesive dries (12-24 hours depending on the season), your personal oven is ready for use.

The heaviest part is the dome, weighing about 200 kg, requiring 3-4 people for installation.

Roof, air ducts, and adhesives are not included in the price and are ordered separately.

Our Useful Tips

Recommendation for MANDATORY Insulation: The better the oven is insulated, the more efficient the baking, as the accumulated heat is retained longer. We recommend placing a ROOF over the dome and filling the empty space with quartz sand or marble flour (200 kg = 8-10 bags of 25 kg each).

Alternatively, you can insulate the oven dome with mineral wool, chicken wire mesh, and finally plaster with chamotte (fireproof mix) or clay.

Idea for a quick, easy, and suitable platform: Order paving stones along with the selected garden item, and you elegantly solve the leveling platform issue without hassle and in a suitable combination.

Български

Български