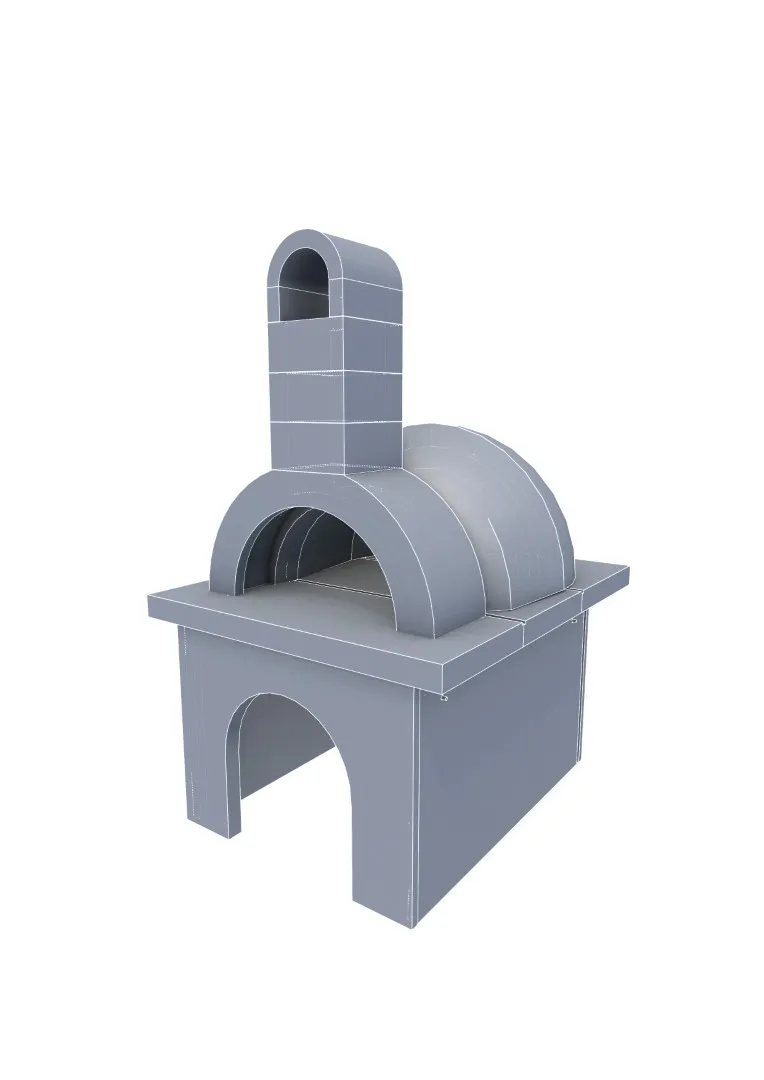

Stone oven | Standard series

| Production lead time | |

| Type cladding | Standard |

| Sizes Garden Barbecues | 120/145/170сm |

| Material | Gneiss |

| Natural stone | Sandy-gold slate |

| Blue grey (Kavala) slate | |

| Finish | Natural |

| Price / Unit | Price for 1 piece |

| Pallet | |

| Weight | 950 kg |

| Delivery via courier to address in Bulgaria | Transport for 1 industrial pallet max. 1 tonne 110 lv + 2% cash-on-delivery tax |

| Natural stone specifics | Possible deviations and variations in the colors and textures of the stone tiles are expected (resulting from the natural origin and formation of the stone). |

| Our products are handmade craftsmanship, made by artisans (stone masons). | |

| Recommended adhesives | Gray polymer adhesive FLEXI (for silicone gun) |

| Black heat-resistant adhesive KALOFER (for silicone gun) | |

| Protection, mandatory impregnation, and maintenance (LTP or AKEMI) | For protection against water absorption: Universal stone impregnator (LTP or AKEMI) |

| For protection against water and grease absorption: Stone impregnator Mattstone H2O | |

| For color enhancement and protection: Wet effect impregnator (LTP or AKEMI). |

The warmth of the hearth and the beauty of the stone create a product that will be used for the most valuable things in life – shared time with loved ones, emotion, laughter, and memorable culinary delights.

Ovens are fired up when we honor our roots and re-create our traditions, creating memories.

The soft shapes and elegance of the natural stone in the Standard oven cladding make it a stunning culinary centerpiece in the garden.

It's important to know that the Standard series oven features:

- A domed structure made of fireproof chamotte bricks using an old Bulgarian technique.

- Reinforced concrete panels and thermo-concrete for the hearth.

- Designed for outdoor use.

- Clad with natural stone (handcrafted by skilled artisans).

- Comes with a metal lid for closing and sealing the oven after heating.

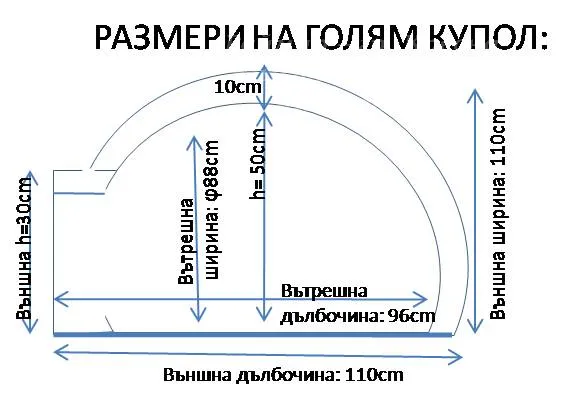

- A dome opening width of 60 cm.

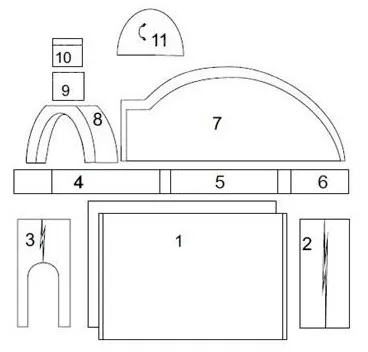

- Arranged elements on a 1x1.20 m pallet for easy transportation.

- The ability to extend the chimney with additional ducts measuring 30x30 cm and 15 cm in height.

- The option to use various accessories.

- Detailed assembly instructions.

- Practical Use and Modular Installation

To use: Place dry wood and twigs in the center of the oven dome. Avoid sudden temperature changes in the combustion chamber by not using blowtorches or petroleum-based products. After initial lighting, it’s normal for the bricks in the dome to blacken. The fire should be maintained until the bricks turn white. The heating process takes about 2-3 hours. Once the bricks turn white, the oven is ready for baking, and you can insert your prepared dish. Finally, close the dome opening with the iron lid and seal the sides with clay or a mixture of ash, flour, and water.

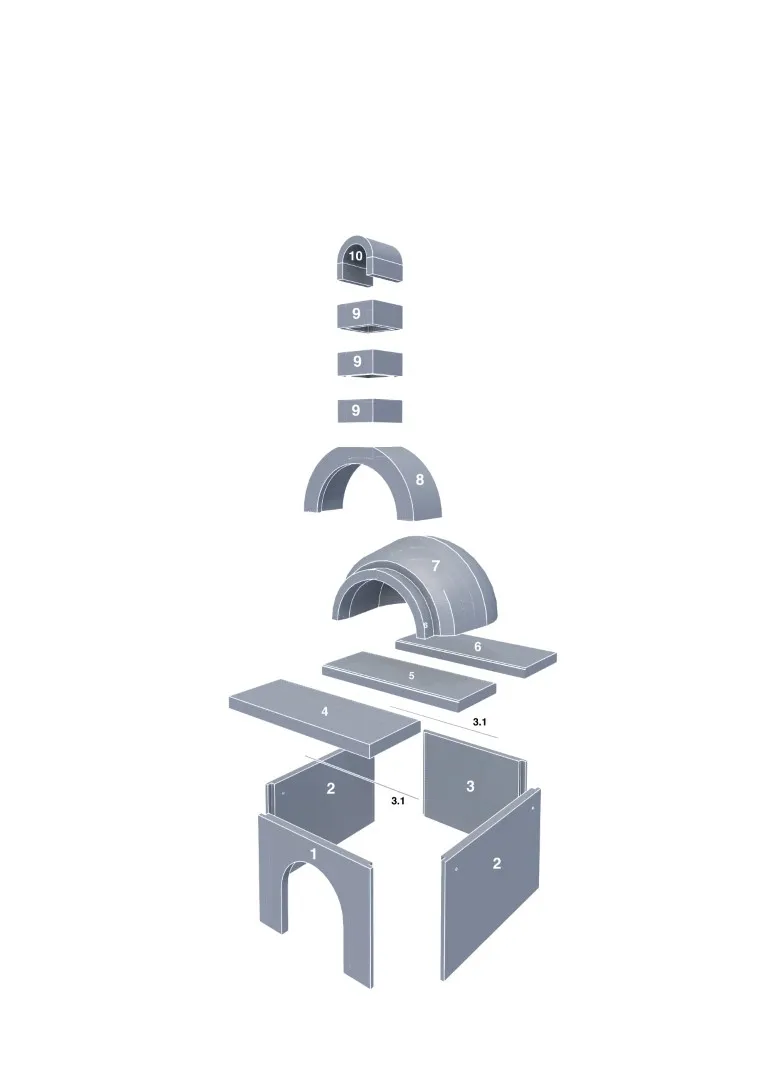

Approximate assembly time for 3-4 beginners: 3-4 hours.

Required adhesives for assembly: 25 kg of class C2 cement-based adhesive + 20 kg of heat-resistant adhesive.

Assembly Instructions:

A critical step for proper and easy assembly of your oven is the foundation. It must be stable, well-leveled, and even. The oven elements are built according to the numbering in the assembly instructions and are glued with class C2 cement-based adhesive. It's recommended to use heat-resistant adhesive for the elements in and around the dome. Before applying the adhesive, thoroughly moisten each part with water to ensure proper bonding. Finally, grout and clean. After the adhesive dries (12 to 24 hours, depending on the season), your oven is ready to use.

The heaviest part is the dome, weighing about 200 kg, requiring 3-4 people to move it.

The roof, ducts, and adhesives are not included in the price and must be ordered separately.

Our Useful Tips

Recommended insulation: The better insulated the oven is, the more efficient the baking, as the accumulated heat is retained longer. We recommend placing a roof over the oven dome and filling the empty space with quartz sand or marble dust (200 kg = 8-10 bags of 25 kg each).

Alternatively, you can insulate the oven dome with aluminum foil-coated wool (3.5-4 sq.m.), expanded metal mesh, and finally plaster with chamotte – a refractory mix of heat-resistant and cement-based adhesive.

Български

Български